Shipping problems don’t just delay freight, they damage trust, increase costs, and expose weak points in operations. Knowing what steps to take to identify the root cause of a shipping problem when it occurs is essential for brokers, shippers, and logistics teams focused on reliability and scale (Council of Supply Chain Management Professionals, n.d.).

This guide breaks down a structured, repeatable approach to shipping problem root cause analysis, using practical frameworks, checklists, and operational tools. The goal is not just to explain failures, but to build systems that prevent them from happening again.

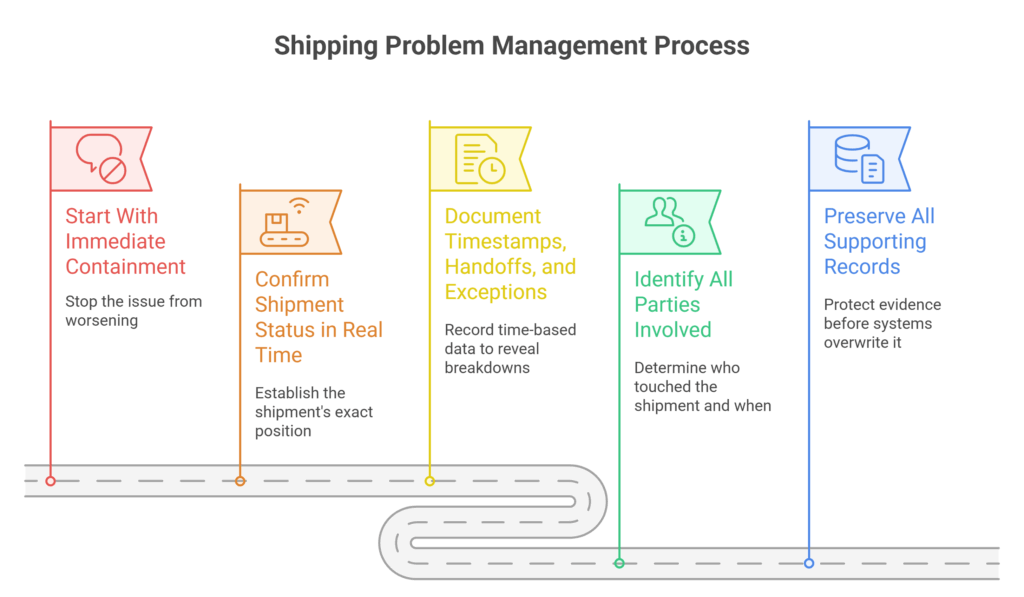

Start With Immediate Containment and Fact Gathering

When a shipping problem occurs, the first priority is not analysis, it’s containment. Containment means stopping the issue from getting worse while preserving accurate information (U.S. Department of Transportation, n.d.). Teams that skip this phase often waste time debating causes instead of grounding decisions in facts.

Immediate fact gathering creates a reliable baseline for every later step in the shipping problem root cause analysis. Without it, investigations become reactive, inconsistent, and prone to bias.

1. Confirm Shipment Status in Real Time

Start by establishing the shipment’s exact position in the lifecycle:

- Was the pickup completed on time?

- Is the freight in transit, stalled, or rerouted?

- Was a delivery attempted or rescheduled?

This step eliminates assumptions and prevents misaligned responses. Many late shipment root cause steps fail because teams argue over where the delay occurred instead of verifying it (Council of Supply Chain Management Professionals, n.d.). Accurate status confirmation is the foundation of any effective shipping error investigation process.

2. Document Timestamps, Handoffs, and Exceptions

Time-based data reveals where breakdowns occur.

Key details to capture:

- Scheduled vs. actual pickup and delivery times

- Dock check-in and check-out timestamps

- Carrier handoff points

- System-generated exceptions or alert

This documentation feeds directly into a shipment delay diagnosis checklist and allows teams to identify patterns later when performing shipping KPI analysis for issues. Missing timestamps almost always lead to incomplete or incorrect conclusions.

3. Identify All Parties Involved

Shipping failures are rarely isolated to one function. Clearly identify:

- Origin warehouse or shipper

- Carrier or driver

- Broker or logistics coordinator

- Consignee or customer

Knowing who touched the shipment and when helps prevent blame-based conclusions and keeps the focus on process gaps. This clarity is critical when building a recurring shipping problems fix, especially in multi-party logistics environments.

4. Preserve All Supporting Records

Evidence must be protected before systems overwrite or delete it.

Preserve:

- Bills of Lading (BOLs)

- Tracking and GPS logs

- ELD records

- Emails, messages, and call logs

- Warehouse management system entries

These records are essential inputs for logistics incident analysis tools, including 5 Whys shipping delays and fishbone diagram logistics issues. Without preserved data, even the best warehouse shipping audit process becomes unreliable.

Why This Step Matters

Immediate containment and fact gathering turn a shipping failure into a controlled incident instead of a chaotic escalation. Teams that standardize this phase:

- Shorten investigation time

- Improve corrective actions shipping errors

- Strengthen preventive measures shipping failures (American Society for Quality, n.d.)

- Support continuous improvement shipping ops

Skipping this step almost guarantees repeat delays, inconsistent fixes, and weak accountability.

“High-performing logistics teams treat incident documentation as a discipline, not a reaction. Clean data collection shortens investigations and improves future response times.”

What information do you usually realize you’re missing after a shipping issue escalates?

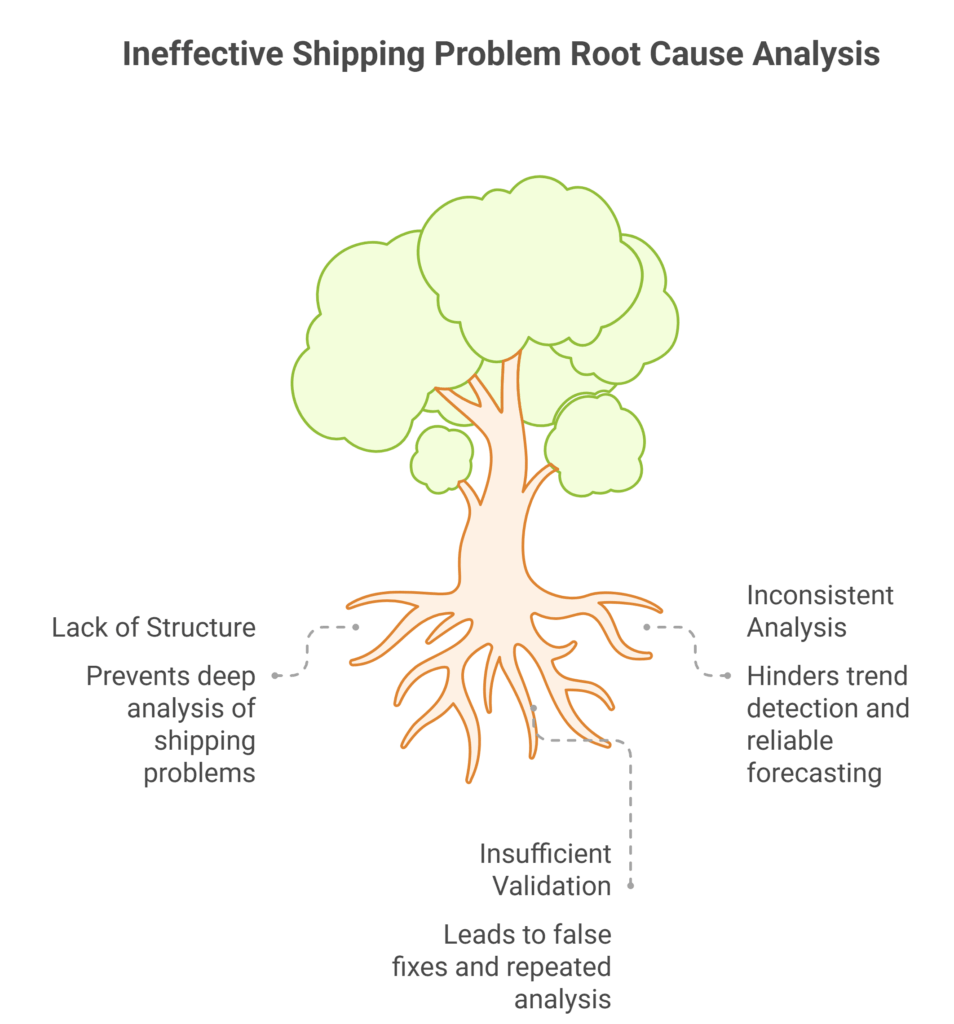

Apply Structured Root Cause Analysis Methods

Once facts are stabilized and documented, the investigation must move from what happened to why it happened. This is where many shipping teams fail, not because they lack effort, but because they lack structure.

A disciplined approach to shipping problem root cause analysis prevents surface-level conclusions and helps organizations build a real recurring shipping problems fix instead of temporary workarounds (American Society for Quality, n.d.).

1. Use the 5 Whys to Break Down Shipping Delays

The 5 Whys shipping delays method forces teams to look past the obvious. Instead of stopping at the first explanation, it pushes analysis deeper into process failures.

Example flow:

-

Why was the shipment late?

→ The truck arrived after the cutoff time. -

Why did the truck arrive late?

→ The load was not staged when the driver arrived. -

Why was the load not staged?

→ Pick completion was delayed. -

Why was pick completion delayed?

→ Labor was reallocated without updating the outbound schedule. -

Why was the schedule not updated?

→ No escalation trigger exists for labor changes.

This process reveals systemic issues rather than individual mistakes. It is one of the most effective logistics incident analysis tools for identifying breakdowns in planning, communication, and execution.

When applied consistently, it strengthens late shipment root cause steps and improves decision-making across teams.

2. Map Contributing Factors With a Fishbone Diagram

The fishbone diagram logistics issues method helps visualize complex shipping failures, especially when multiple variables interact.

Common categories include:

- People: training gaps, communication failures

- Process: missing SOPs, unclear ownership

- Equipment: dock constraints, system downtime

- Environment: weather, congestion, facility layout

- Systems: WMS, TMS, integration failures

This visual mapping prevents tunnel vision and supports a more complete root cause analysis freight shipping approach. It is particularly effective during cross-functional reviews involving warehouse, operations, and carrier management teams.

Fishbone diagrams also integrate cleanly into a standardized supply chain root cause template, making them easy to reuse and scale.

3. Standardize Findings Using Root Cause Templates

Consistency matters. Without it, every incident is analyzed differently, making trend detection nearly impossible.

A strong supply chain root cause template should include:

- Incident summary

- Timeline of events

- Identified root causes

- Impact assessment

- Recommended corrective actions shipping errors

- Proposed preventive measures shipping failures

Standard templates ensure the shipping error investigation process produces comparable insights across incidents (Transportation Research Board, n.d.). Over time, this structure enables stronger shipping KPI analysis for issues and more reliable operational forecasting.

4. Validate Findings Before Taking Action

Before implementing fixes, root causes must be validated against evidence.

Validation steps include:

- Cross-checking against timestamps and audit data

- Reviewing similar past incidents

- Confirming assumptions with frontline teams

- Testing whether the root cause explains all observed failures

This step prevents false fixes and strengthens the credibility of late shipment root cause steps. Teams that skip validation often repeat the same analysis cycle without meaningful improvement.

Why This Step Matters

Structured analysis transforms incidents into intelligence. When organizations rely on frameworks like 5 Whys shipping delays, fishbone diagram logistics issues, and standardized templates, they build operational memory.

This approach:

- Improves the quality of corrective actions shipping errors

- Reduces repeat incidents

- Strengthens preventive measures shipping failures

- Supports long-term continuous improvement shipping ops

Without structured analysis, shipping failures become noise instead of signals.

“The biggest root cause of mistakes is stopping analysis once a person or partner is identified. True fixes live in processes, not individuals.”

Which method has helped your team go deeper, the 5 Whys or visual mapping like fishbone diagrams?

Audit the Physical and Operational Workflow

After identifying probable root causes, the next step is to verify whether the physical and operational environment supports reliable execution. Many shipping failures persist not because teams misunderstand the cause, but because process gaps inside the warehouse or operations floor go unexamined(Transportation Research Board, n.d.).

A structured warehouse shipping audit process bridges the gap between analysis and reality. It validates whether day-to-day execution aligns with documented procedures and system expectations.

1. Review Pick, Pack, and Staging Accuracy

Shipping delays often begin long before a truck arrives.

Key areas to audit:

- Pick completion times versus planned wave schedules

- Accuracy of item selection and quantities

- Packaging compliance with carrier requirements

- Staging location readiness at dock doors

Misalignment in any of these areas frequently surfaces later as late shipment root cause steps. When pick or pack delays are normalized, they quietly undermine the entire shipping error investigation process.

Auditing these steps provides direct insight into whether corrective actions shipping errors should focus on labor planning, system configuration, or training.

2. Evaluate Dock Scheduling and Door Utilization

Dock congestion is a silent driver of recurring delays.

Audit the following:

- Appointment adherence (early, on-time, late arrivals)

- Door assignment logic

- Turnaround time per load

- Conflicts between inbound and outbound movements

A weak dock schedule often creates cascading failures that appear as carrier delays but originate internally. Including dock performance in a shipment delay diagnosis checklist improves accuracy and supports a true recurring shipping problems fix.

3. Assess Load Sequencing and Labeling Controls

Incorrect load order and labeling issues frequently trigger re-handling, missed departures, or rejected deliveries.

Audit controls such as:

- Load build sequencing based on route priority

- Pallet and carton labeling accuracy

- Scanning compliance at final load verification

- Exception handling for last-minute changes

These checks are essential inputs for root cause analysis freight shipping, especially when delays occur despite on-time carrier arrival. Small execution errors at this stage often require disproportionate recovery effort later (Council of Supply Chain Management Professionals, n.d.).

4. Verify System-to-System Data Flow

Technology failures often masquerade as operational mistakes.

Audit:

- WMS to TMS data synchronization

- Appointment scheduling integrations

- Carrier visibility and tracking updates

- Alert thresholds and escalation rules

Breakdowns here weaken logistics incident analysis tools and distort shipping KPI analysis for issues. If systems disagree, teams chase symptoms instead of causes.

This validation step strengthens both corrective actions shipping errors and preventive measures shipping failures by ensuring systems reflect reality.

5. Compare Audit Findings Against Historical Incidents

Audit results gain value when compared with past failures.

Look for:

- Repeated process breakdowns

- Consistent bottlenecks

- Patterns tied to volume spikes or labor shifts

- Correlations with past late shipment root cause steps

This comparison connects audits directly to continuous improvement shipping ops and prevents audits from becoming one-time exercises with no lasting impact.

A formal warehouse shipping audit process often reveals hidden inefficiencies that trigger delays downstream. Pair audits with shipping KPI analysis for issues such as dwell time, missed pickups, and exception frequency.

This stage is critical in late shipment root cause steps, especially when delays appear random but follow internal patterns. Without audits, teams struggle to implement a real recurring shipping problems fix.

“Most carrier delays originate from warehouse readiness gaps. Audits expose issues dashboards never show.”

Are hidden process gaps causing repeat shipping delays? Discover how our freight broker solutions help identify workflow breakdowns and optimize shipping operations.

Implement Corrective and Preventive Actions

Identifying the cause means nothing without follow-through. Strong organizations separate corrective actions shipping errors from preventive measures shipping failures.

Corrective Actions: Fix the Immediate Breakdown

Corrective actions focus on restoring normal operations and addressing the specific failure that occurred (Council of Supply Chain Management Professionals, n.d.).

Common corrective actions include:

- Updating SOPs where execution deviated from plan

- Retraining staff on affected processes

- Enforcing carrier compliance requirements

- Adjusting cut-off times or appointment rules

- Fixing system configuration or data errors

These actions should directly tie back to findings from the shipping error investigation process. Poorly defined corrections often fail to resolve late shipment root cause steps and increase the risk of repeat incidents.

Preventive Measures: Stop the Failure From Returning

Preventive measures address why the issue was allowed to occur in the first place.

Examples include:

- Adding pre-dispatch validation checks

- Automating alerts for schedule or labor changes

- Introducing standardized supply chain root cause templates

- Strengthening cross-team communication protocols

- Expanding shipping KPI analysis for issues

When preventive measures shipping failures are properly implemented, teams move from reaction to resilience and strengthen continuous improvement shipping ops over time.

Track Effectiveness and Adjust

Actions must be monitored to ensure they work.

Track:

- Reduction in repeat incidents

- Improvement in on-time performance

- Decrease in manual interventions

- Consistency across shifts or locations

This feedback loop ensures corrective actions shipping errors and preventive measures shipping failures remain effective and evolve as operations scale (Transportation Research Board, n.d.).

“Corrective actions stop the bleeding. Preventive measures eliminate the disease.”

Are your shipping operations fully protected against recurring errors? Explore our compliance and risk management solutions to implement effective corrective and preventive actions.

Frequently Asked Questions(FAQs)

1. What is the most effective way to analyze shipping delays?

Combining a shipment delay diagnosis checklist with structured tools like 5 Whys shipping delays and fishbone diagram logistics issues provides the clearest insights.

2. How do I prevent the same shipping problems from happening again?

Focus on preventive measures shipping failures, not just corrective actions shipping errors. Prevention requires process redesign and KPI tracking.

3. Should every shipping issue go through a full root cause analysis?

High-impact or recurring issues should always go through full shipping problem root cause analysis, while minor exceptions can follow a simplified review.

Turn Shipping Disruptions into Operational Strength

Shipping problems are inevitable. Repeated failures are not. By following structured late shipment root cause steps, using proven analysis frameworks, enforcing a warehouse shipping audit process, and separating corrective actions from preventive measures, logistics teams can turn disruptions into operational advantages.

A disciplined approach to root cause analysis freight shipping strengthens reliability, protects margins, and builds trust across the supply chain.

Want to reduce repeat delays and build more resilient freight operations? Contact us to strengthen your shipping processes and move freight with confidence.

References

American Society for Quality. (n.d.). Root cause analysis tools and techniques. Retrieved from https://asq.org

Council of Supply Chain Management Professionals. (n.d.). Shipping KPI and performance metrics. Retrieved from https://cscmp.org

Transportation Research Board. (n.d.). Supply chain root cause templates and case studies. Retrieved from https://www.trb.org

U.S. Department of Transportation. (n.d.). Freight shipping error investigation process. Retrieved from https://www.transportation.gov