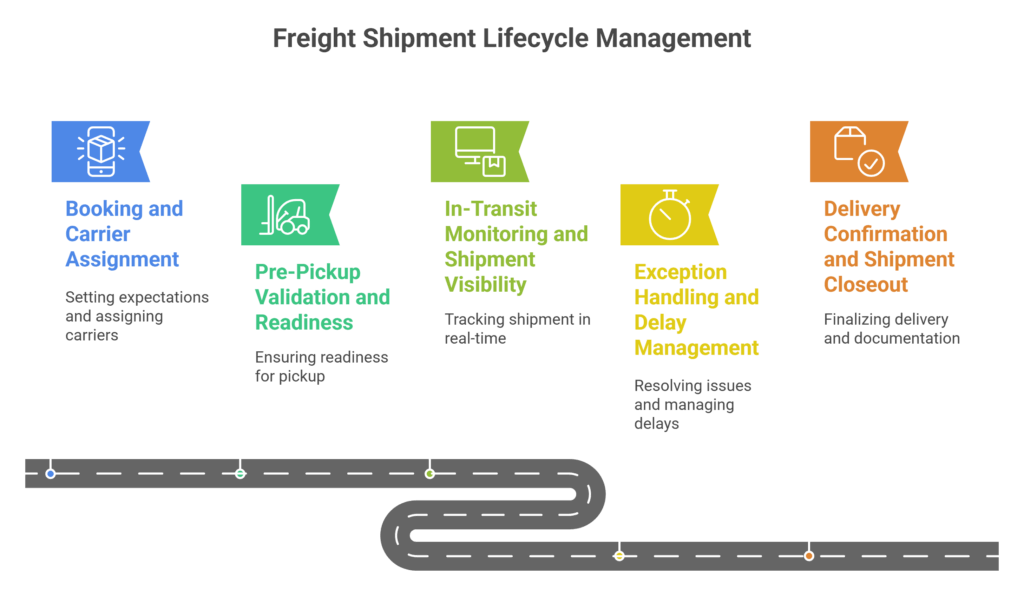

Managing a freight shipment is no longer just about moving cargo from Point A to Point B. Nowadays, success depends on visibility, precision, and proactive control across every stage of the shipment journey. Strong freight shipment lifecycle management reduces disruptions, improves customer trust, and protects margins (Council of Supply Chain Management Professionals [CSCMP], n.d.).

Below is a practical, end-to-end guide to managing the lifecycle of a freight shipment from booking to delivery confirmation, using proven operational best practices used by high-performing brokers and logistics teams .

1. Booking and Carrier Assignment

Booking is where expectations are set and risk is either reduced or introduced. Following disciplined freight booking best practices ensures that pricing, service requirements, and execution responsibilities are clear from the start (FMCSA, n.d.).

Key Best Practices

- Verify shipment details (commodity, weight, dimensions, accessorials)

- Confirm pickup and delivery windows with both shipper and carrier

- Validate carrier authority, insurance, and equipment compatibility

- Document rates, fuel surcharges, detention, and layover terms clearly

Applying standardized freight booking best practices consistently reduces downstream disputes, missed pickups, and preventable exceptions. This stage directly impacts on-time delivery metrics freight, because inaccurate bookings almost always lead to late deliveries.

Strong booking discipline is the foundation of effective freight shipment lifecycle management.

“Most freight problems aren’t transit problems, they’re booking problems that surface later.”

What booking details cause the most downstream issues in your operation, and how could tighter booking standards prevent them?

2. Pre-Pickup Validation and Readiness

Once a load is booked, pre-pickup execution determines whether the shipment starts smoothly or immediately enters exception status (FreightWaves, n.d.). A structured daily freight operations checklist is essential at this stage.

Daily Freight Operations Checklist Essentials

- Carrier and driver fully confirmed

- Pickup appointment verified with the shipper

- Driver contact and tracking method validated

- Backup carrier identified if risk exists

- Shipment entered correctly in freight broker tracking systems

Using a daily freight operations checklist creates operational consistency, especially across high-volume desks. Teams that rely on checklists experience fewer missed pickups and better on-time delivery metrics freight (Gartner, n.d.).

This step also activates real-time freight tracking, ensuring visibility begins before the truck moves.

“Pre-pickup is where professionals separate themselves from reactive operators.”

Which pre-pickup tasks are still handled informally in your operation, and what risks does that create?

3. In-Transit Monitoring and Shipment Visibility

In-transit execution is where visibility, communication, and technology intersect. Real-time freight tracking is no longer optional, it is the backbone of modern end-to-end freight operations.

Tools That Enable In-Transit Control

- Freight broker tracking systems for centralized updates

- Cargo tracking software with GPS, geofencing, and alerts

- Integrated shipment visibility tools for shipper transparency

Effective real-time freight tracking allows teams to identify delays early and initiate proactive shipment issue resolution instead of waiting for customers to ask questions.

Visibility enables faster freight lifecycle problem solving and builds trust with shippers who value predictability.

“Visibility doesn’t eliminate delays, it eliminates surprises.”

Struggling to maintain real-time visibility and stay ahead of shipment issues before customers notice? Explore modern freight broker technology designed to improve tracking, alerts, and shipment transparency across your operation.

4. Exception Handling and Delay Management

No freight operation is exception-free. What matters is how consistently and quickly issues are resolved. Structured freight exception management ensures problems are handled professionally and predictably (FMCSA, n.d.).

Shipment Delay Troubleshooting Framework

- Identify the root cause (weather, traffic, facility congestion, mechanical)

- Assess service impact and updated ETA

- Communicate clearly with all stakeholders

- Offer alternatives or recovery options if needed

Strong shipment delay troubleshooting prevents escalation and protects relationships. When supported by proactive shipment issue resolution, teams can often turn disruptions into proof of reliability (CSCMP, n.d.).

Disciplined freight exception management reduces claims, improves service scores, and strengthens long-term shipper trust.

“Customers judge you less on whether problems happen and more on how fast you take control.”

Do your customers learn about delays from you first, or do they notice them before you do?

5. Delivery Confirmation and Shipment Closeout

Delivery is not complete until documentation and system closeout are finalized. A clean proof of delivery process protects cash flow and prevents disputes.

Why the Proof of Delivery Process Matters

The proof of delivery process serves three critical functions:

- Confirms the shipment was delivered as agreed

- Triggers invoicing and payment

- Protects brokers and carriers during disputes, audits, and claims

Without a standardized proof of delivery process, organizations face delayed billing, rejected invoices, accessorial disputes, and customer mistrust, all of which directly impact margins.

Proof of Delivery Process Best Practices

1. Confirm Delivery Time, Condition, and Location

Immediately verify:

- Actual delivery date and time

- Delivery location and consignee

- Freight condition (shortages, damage, or exceptions noted)

Accurate confirmation ensures alignment with on-time delivery metrics freight and prevents post-delivery disputes. Any exceptions must be documented before the driver leaves the facility.

2. Collect Signed POD Immediately

Timely collection is critical.

Best practices include:

- Digital POD capture through freight broker tracking systems

- Photo documentation when applicable

- Automated reminders to drivers and carriers

Delays in POD collection slow billing cycles and weaken leverage during claims. A disciplined proof of delivery process prioritizes POD retrieval as a same-day requirement, not an afterthought.

3. Validate Accessorial Charges

Before invoicing:

- Confirm detention, layover, lumper, or re-delivery charges

- Match charges against agreed terms from booking

- Ensure supporting documentation is attached

This step connects delivery closeout with upstream freight booking best practices, ensuring consistency between what was agreed and what is billed.

4. Close the Shipment in the System

Shipment closeout should include:

- POD uploaded and verified

- Charges finalized and approved

- Shipment status updated in freight broker tracking systems

- Billing triggered automatically

Systematic closeout ensures accurate reporting, supports freight KPI tracking, and improves data integrity across end-to-end freight operations.

A standardized proof of delivery process improves billing accuracy and audit readiness. Repeating the proof of delivery process consistently reduces payment delays and strengthens operational credibility.

This final step closes the loop in freight shipment lifecycle management.

Operational Benefits of a Standardized Closeout Process

A consistent proof of delivery process delivers measurable advantages:

- Faster invoicing and improved cash flow

- Reduced billing disputes and chargebacks

- Stronger audit and compliance readiness

- More reliable performance data for analytics

Repeated execution of the proof of delivery process strengthens organizational discipline and reinforces trust with shippers and carriers alike.

Common Closeout Failures to Avoid

- Waiting days to request PODs

- Accepting incomplete or illegible documentation

- Billing before validating accessorial

- Closing shipments manually without system verification

These gaps undermine freight lifecycle problem solving and create unnecessary financial risk.

“Revenue leakage in freight rarely comes from rates, it comes from weak closeout discipline.”

Want to ensure every shipment is delivered and documented flawlessly? Watch this video on mastering freight shipment lifecycle from booking to delivery.

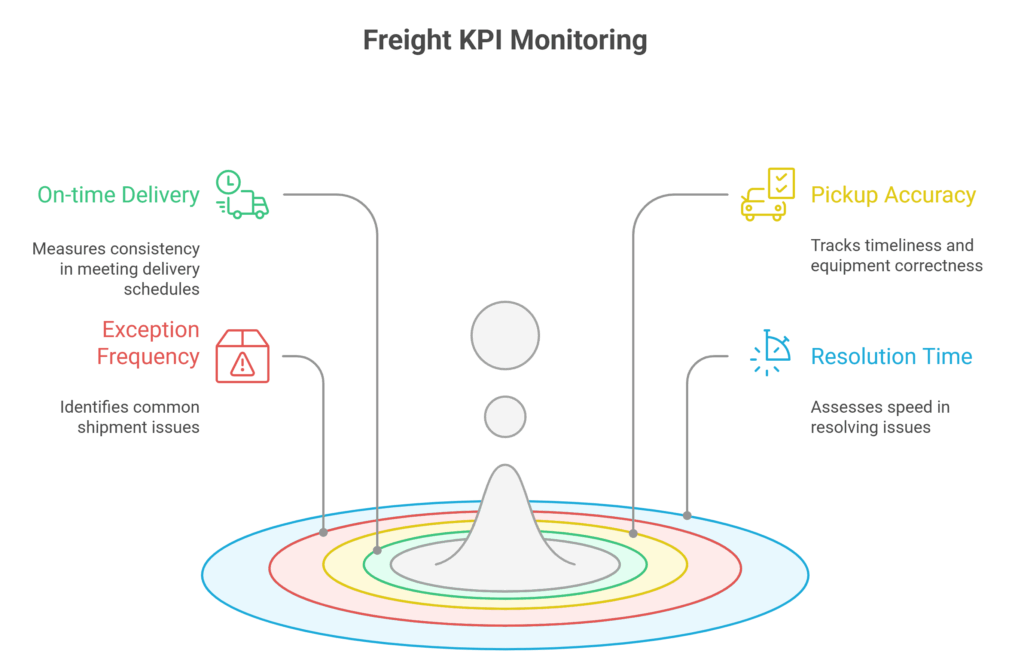

Measuring Performance With Freight KPIs

You can’t improve what you don’t measure. Consistent freight KPI tracking turns daily activity into actionable insight and ensures accountability across teams, carriers, and customers. Without clear KPIs, freight operations rely on anecdotal feedback instead of data-driven decisions.

Well-defined KPIs allow leaders to identify trends, diagnose systemic issues, and continuously refine end-to-end freight operations.

Key Freight KPIs to Monitor

-

On-time delivery metrics freight

Measures how consistently shipments arrive within agreed delivery windows. This KPI reflects the combined effectiveness of booking accuracy, carrier performance, and exception handling. Persistent issues here often point to upstream failures, not just transit delays. -

Pickup accuracy rate

Tracks whether carriers arrive on time and with the correct equipment. Low pickup accuracy typically signals gaps in freight booking best practices or weak pre-pickup validation. -

Exception frequency

Measures how often shipments encounter issues such as delays, rejections, or documentation problems. High exception rates indicate weaknesses in planning, communication, or freight exception management. -

Average resolution time

Captures how quickly issues are resolved once identified. Faster resolution times demonstrate effective proactive shipment issue resolution and strong internal workflows.

Together, these KPIs provide a balanced view of reliability, responsiveness, and execution quality. When reviewed consistently, freight KPI tracking enables smarter decisions, stronger carrier management, and measurable improvement across end-to-end freight operations (DAT Freight & Analytics, n.d.).

How to Use KPIs Effectively

- Review KPIs weekly, not just monthly

- Tie performance metrics to specific process owners

- Compare internal performance against customer expectations

- Use KPI trends to drive SOP updates and training

KPIs are only valuable when they influence behavior and process improvements.

“KPIs don’t exist to assign blame, they exist to reveal where the system needs to improve.”

Which freight KPI has the biggest impact on your customer relationships toda, and how often do you actively review it with your team?

Frequently Asked Questions(FAQs)

1. What is freight shipment lifecycle management?

It’s the process of managing a shipment from booking through delivery confirmation, including tracking, exception handling, and performance measurement.

2. Why is real-time freight tracking important?

Real-time freight tracking improves visibility, enables faster response to delays, and supports stronger customer communication.

3. How do on-time delivery metrics impact freight operations?

Tracking on-time delivery metrics freight helps identify operational weaknesses and improve service reliability over time.

Elevate Your Freight Operations

Managing freight effectively requires discipline at every stage. From applying strong freight booking best practices, using a consistent daily freight operations checklist, leveraging shipment visibility tools, and executing a clean proof of delivery process, every step matters.

When supported by freight broker tracking systems, cargo tracking software, and robust freight KPI tracking, logistics teams gain control, resilience, and measurable performance improvements.

Ready to tighten operations and gain full visibility across every load? Contact us to optimize your freight processes and operate with confidence.

References

Council of Supply Chain Management Professionals. (n.d.). Supply chain management definitions and practices. Retrieved from https://www.cscmp.org

DAT Freight & Analytics. (n.d.). Freight market analytics and carrier performance insights. Retrieved from https://www.dat.com

Federal Motor Carrier Safety Administration. (n.d.). Carrier compliance and operational guidelines. Retrieved from https://www.fmcsa.dot.gov

FreightWaves. (n.d.). Freight operations and logistics trends. Retrieved from https://www.freightwaves.com

Gartner. (n.d.). Logistics visibility and performance measurement research. Retrieved from https://www.gartner.com