Freight brokerage success isn’t built solely on sales, it’s earned through seamless daily operations, proactive communication, and reliable problem-solving. From managing the complete lifecycle of a shipment to handling unexpected disruptions, brokers who excel operationally win the trust of shippers and carriers alike. This guide explores actionable strategies to optimize daily freight operations, improve reliability, and strengthen shipper relationships.

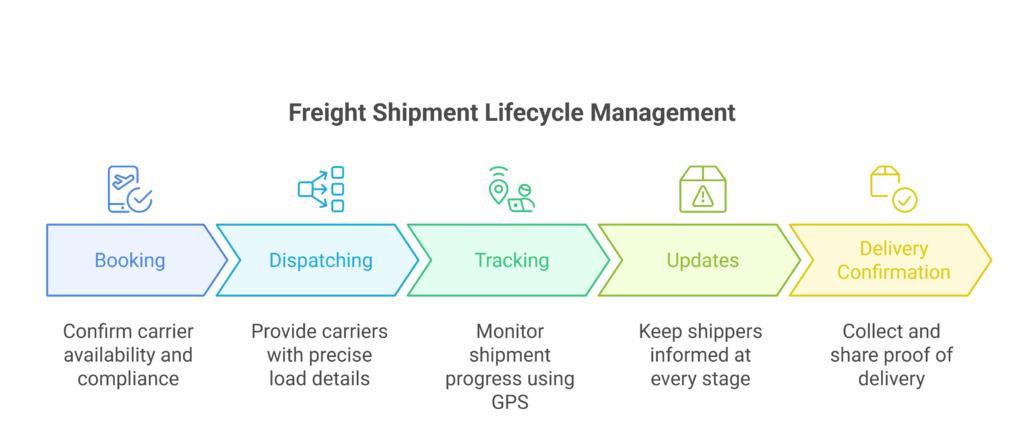

Best Practices for Managing the Freight Shipment Lifecycle

The shipment lifecycle includes multiple touchpoints where brokers must ensure accuracy, efficiency, and transparency (National Motor Freight Traffic Association [NMFTA], n.d.).

Key steps:

- Booking: Confirm that a carrier is available with the right equipment. Verify insurance coverage, safety rating, and compliance requirements to prevent liability issues. Use multiple carrier options to avoid last-minute scrambling.

- Dispatching: Provide carriers with precise load details such as addresses, appointment times, commodity type, and any special instructions. Clear communication minimizes misunderstandings (Freightquote, n.d.).

- Tracking: Use GPS-enabled platforms or ELD integrations to monitor shipment progress. Establish check-in intervals or automated alerts for real-time visibility.

- Updates: Keep shippers informed at every stage. Send proactive notifications for delays, early arrivals, or any exceptions, rather than waiting for them to ask.

- Delivery Confirmation: Collect a signed proof of delivery (POD) and share it with the shipper immediately. Confirm that all load instructions were followed and note any discrepancies for records (Freightquote, n.d.).

“High-performing brokers use automation to manage repetitive tasks like status updates, freeing up time to handle exceptions and build stronger shipper relationships.”

Which part of the freight lifecycle creates the most challenges for your brokerage, booking, tracking, or delivery confirmation?

Real-Time Shipment Tracking

Accurate shipment visibility builds trust and reduces customer anxiety.

Best practices for real-time tracking:

- GPS-integrated platforms: These provide live location data so shippers know exactly where the truck is (Freightquote, n.d.).

- Automated updates: APIs or EDI connections automatically send progress reports, saving time on manual calls (FreightRun, n.d.).

- Condition monitoring: For reefer loads, track temperature and humidity to ensure compliance with customer requirements.

- Proactive ETAs: Share new delivery times when conditions change instead of waiting for the shipper to request updates.

“Visibility isn’t just a value-add anymore, it’s an expectation. Shippers rank reliable updates as one of the top reasons for broker loyalty.”

Do you currently rely on manual check calls, or have you implemented automated tracking tools?

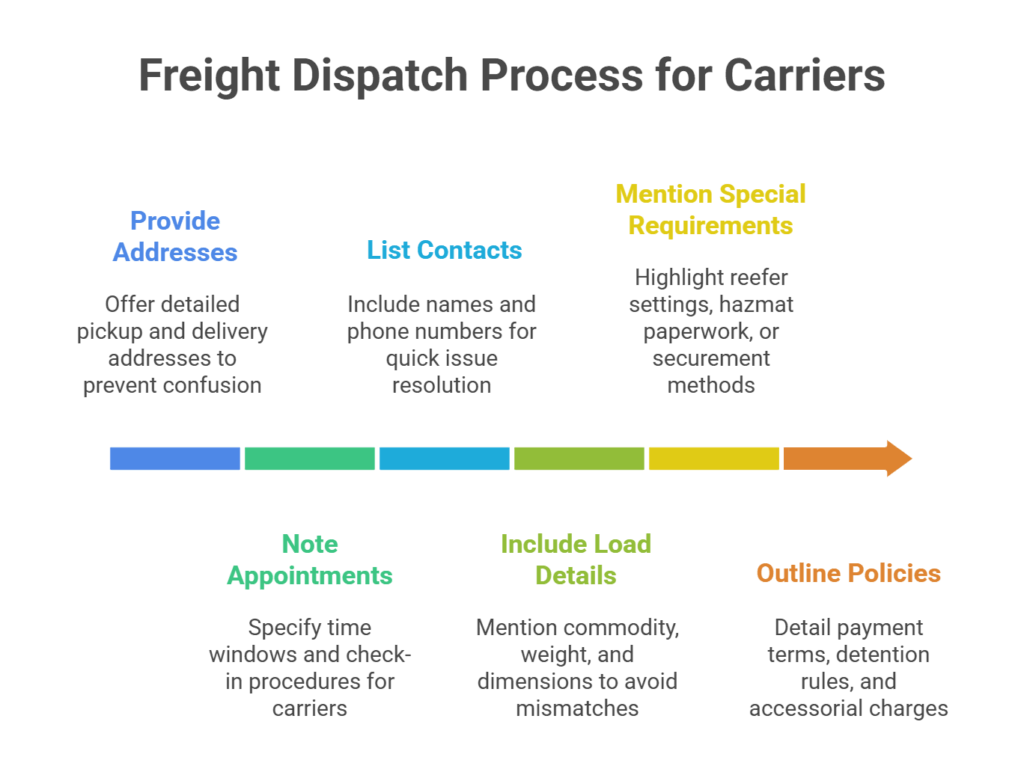

Building a Comprehensive Freight Dispatch Process for Carriers

Clear dispatch instructions reduce errors and increase carrier satisfaction.

Must-have information in dispatch:

- Addresses: Provide both pickup and delivery addresses with gate or dock details to prevent confusion at facilities.

- Appointments: Note time windows and required check-in procedures, ensuring carriers arrive prepared.

- Contacts: List names and phone numbers for shipper/receiver reps so drivers can resolve issues quickly.

- Load details: Include commodity, weight, and dimensions to prevent mismatched equipment or capacity issues.

- Special requirements: Mention reefer settings, hazmat paperwork, or securement methods for safety and compliance.

- Policies: Outline payment terms, detention rules, and accessorial charges to set clear expectations.

“Clarity in dispatch documents prevents 80% of operational disputes between brokers and carriers.”

Looking to take control of your freight career? Discover how to start your own freight brokerage here.

Operational Challenges for Independent Brokers and How to Solve Them

Independent brokers often face unique hurdles that can affect reliability and growth.

Frequent challenges include:

- Carrier no-shows: Drivers may fail to appear for scheduled pickups, causing delays and angry shippers. This can disrupt tight schedules and reduce trust.

- Equipment mismatches: Trucks may not have the required capacity or configuration for a load, leading to last-minute reassignments or cancellations(FreightRun, n.d.).

- Appointment scheduling conflicts: Conflicting or double-booked pickup/delivery times can create delays, fines, or missed windows with shippers.

- Limited tech resources: Small brokerages may lack advanced TMS or tracking systems, making communication, documentation, and load visibility harder (FreightRun, n.d.).

Solutions:

- Build strong carrier networks with backups: Maintain multiple vetted carriers per lane so you can quickly replace no-shows. Keep communication channels open and offer incentives for reliability.

- Verify equipment early: Confirm truck type, capacity, and special requirements before assignment. Double-check with carriers to prevent mismatches.

- Confirm appointments in writing: Send written confirmation of all pickup and delivery windows, including contact info, to both carriers and shippers to reduce conflicts.

- Leverage affordable digital tools (load boards, TMS-lite systems): Use cost-effective technology for dispatch, tracking, and document management to improve efficiency, reduce errors, and allow better oversight of daily operations.

“Independent brokers win by being more flexible and personal than big brokerages, but that requires proactive problem management and strong operational discipline.”

Which operational challenge impacts your business most frequently, and how have you addressed it?

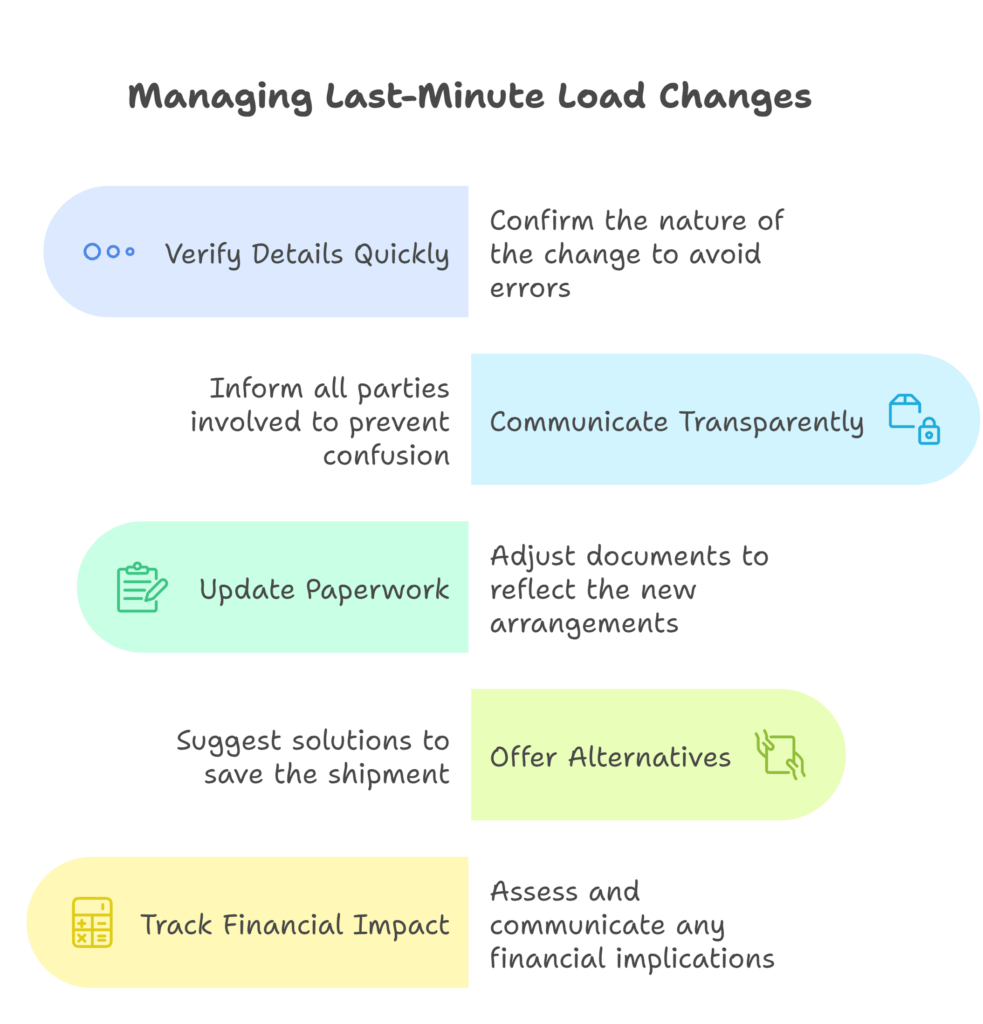

Handling Last-Minute Load Cancellations or Major Shipment Changes

Flexibility is critical when shippers or carriers make unexpected changes.

Steps to manage cancellations/changes:

- Verify details quickly: Confirm whether the load is canceled, rescheduled, or modified. Accuracy avoids wasted effort.

- Communicate transparently: Call both carrier and shipper immediately to prevent confusion. Provide written confirmation afterward for records.

- Update paperwork: Adjust rate confirmations, load tenders, or bills of lading to reflect changes accurately.

- Offer alternatives: Suggest another carrier, modified route, or rescheduled delivery time to save the shipment.

- Track financial impact: Assess whether cancellation fees or new rates apply, and communicate this clearly.

“Fast, honest communication during cancellations determines whether a shipper views you as a trusted partner or a disposable vendor.”

How do you ensure that sudden changes don’t damage your relationships with carriers?

Communicating Delays and Issues to Shippers

Best practices for communicating disruptions:

- Notify early: Call the shipper as soon as a delay is anticipated, even before it becomes critical (uShip, n.d.).

- Be transparent: Explain the cause (e.g., weather, traffic, equipment failure) honestly without deflecting blame.

- Offer solutions: Provide alternatives such as rerouting, rescheduling, or expedited recovery.

- Give updated ETAs: Set realistic expectations instead of vague promises.

- Follow up: After the issue is resolved, confirm the new delivery time and thank the shipper for their patience (uShip, n.d.).

“Shippers value honesty more than perfection, transparent updates during disruptions are the foundation of long-term trust.”

When you communicate delays, do you lead with the problem first or the solution first?

Developing Contingency Plans for Transportation Problems

No matter how prepared you are, disruptions are inevitable. Contingency planning minimizes damage.

Key elements of contingency planning:

- Identify common risks: Weather, equipment breakdowns, driver shortages, or facility delays.

- Create playbooks: Document standard operating procedures for each scenario so staff can act fast.

- Maintain backup carriers: Build relationships with secondary carriers ready to step in (uShip, n.d.).

- Ensure 24/7 support: Rotate after-hours staff or use call centers to manage urgent issues.

- Test your plans: Run scenario drills to uncover weaknesses before real crises happen.

“Contingency planning separates brokers who survive disruptions from those who lose customers.”

Looking to strengthen your brokerage operations and scale efficiently? Discover how to scale your freight brokerage and improve your contingency planning.

Understanding Shipper Lead Times

Shippers vary in how much notice they provide to brokers, and understanding these timelines helps brokers prepare capacity more effectively.

General patterns:

- Contract freight (3–7 days’ notice): Shippers with long-term contracts often schedule freight movements in advance, typically giving brokers a few days to line up carriers. This predictability allows brokers to optimize planning and negotiate better rates.

- Spot freight (same day or within 24 hours): When shippers need urgent capacity, loads are often tendered with little notice. Brokers must act quickly, using load boards or established carrier relationships to secure trucks on short timelines.

- Specialized freight (1 week or more): Freight that requires unique equipment, permits, or handling instructions (such as oversized loads, hazmat, or high-value goods) usually comes with higher costs and longer transit times due to the additional planning, regulatory compliance, and safety precautions involved.

Check out our detailed YouTube video walkthrough on mastering daily freight brokerage operations, tracking, and problem-solving: Watch Now

Frequently Asked Questions (FAQs)

1. What is the most important factor in daily freight operations?

Reliable communication and accurate updates are the foundation of successful brokerage operations.

2. How can small freight brokerages compete with large ones operationally?

By using cost-effective tech tools, focusing on personal relationships, and being more agile with problem-solving.

3. What’s the best way to prepare for unexpected disruptions?

Develop a contingency plan with backup carriers, escalation protocols, and real-time visibility tools.

Winning with Operational Excellence

Daily freight brokerage operations aren’t just about moving loads, they’re about consistency, transparency, and trust. Brokers who master proactive tracking, effective communication, and structured problem-solving gain a competitive edge that translates into long-term customer retention.

Ready to optimize your daily freight operations and boost efficiency? Contact us to implement expert strategies for operational excellence.

References

- Freightquote. (n.d.). LTL freight rates and quoting. Retrieved from https://www.freightquote.com

- FreightRun. (n.d.). LTL freight quote calculator. Retrieved from https://www.freightrun.com

- National Motor Freight Traffic Association. (n.d.). Freight classification guide. Retrieved from https://www.nmfta.org

- uShip. (n.d.). LTL shipping rates. Retrieved from https://www.uship.com