When it comes to shipping efficiency, maximum pallet height can make or break your logistics strategy. Whether you’re moving goods across town or across oceans, knowing the maximum pallet height for shipping ensures your freight is compliant, cost-effective, and safe. From max pallet height for LTL shipments to specialized sea freight requirements, understanding these limits will help you avoid penalties, prevent damage, and optimize your load space.

What is Pallet Shipping?

Pallet shipping involves stacking and securing goods on a wooden, plastic, or metal platform (the pallet) so they can be transported more efficiently using forklifts, pallet jacks, or automated systems (National Wooden Pallet & Container Association [NWPCA], n.d.).

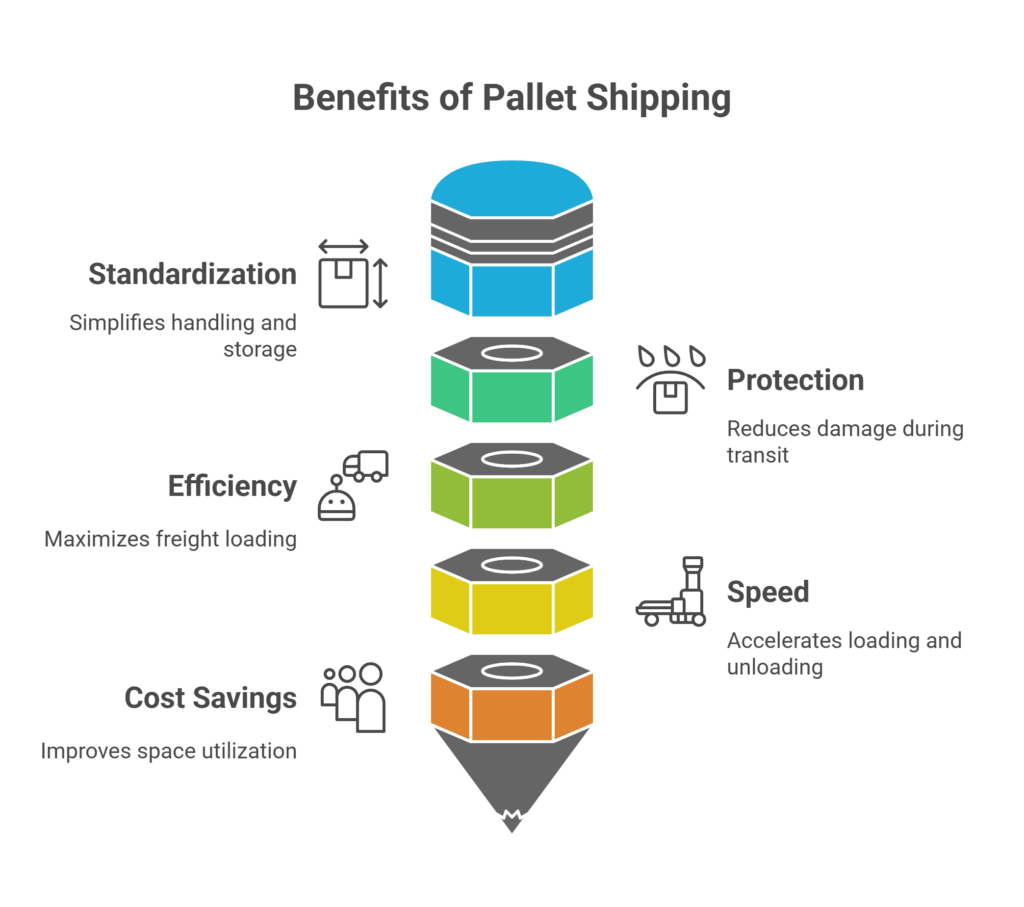

Key reasons companies use pallet shipping:

- Standardization: Makes it easier to handle and store goods.

- Protection: Reduces damage risk during transit.

- Efficiency: Allows more freight to be loaded into trucks or containers.

- Speed: Quicker loading/unloading compared to loose cargo.

- Cost savings: Better use of available truck or container space.

“Pallet shipping revolutionizes freight handling by standardizing how goods are stacked and secured on pallets, enabling faster, safer, and more efficient transport through streamlined loading, reduced damage, and optimized use of space across multiple transport modes.”

How has the adoption of pallet shipping transformed supply chain efficiency and freight handling across different industries?

The Benefits of Knowing Pallet Height

Knowing the maximum pallet height for shipping is not just a technical detail, it’s a cost and compliance advantage.

Benefits include:

1. Avoiding Rejections: Exceeding the pallet height limit can lead to freight being refused by carriers.

2. Optimizing Load Space: Understanding the max pallet height for LTL or sea freight allows you to fit the maximum amount of goods legally and safely.

3. Preventing Damage: Overloaded pallets are more likely to topple or crush goods.

4. Reducing Surcharges: Many carriers charge extra for oversized pallets that exceed the standard pallet height for shipping.

5. Ensuring Global Compatibility: For international freight, different countries and shipping methods have different limits, knowing the maximum pallet height for sea freight is crucial.

“Understanding the maximum pallet height for shipping is critical for avoiding costly rejections, maximizing load capacity, preventing damage, minimizing surcharges, and ensuring compliance with diverse global freight regulations.”

In what ways can precise knowledge of pallet height limits impact shipping costs, safety, and international logistics compliance?

Factors That Influence Pallet Height Choices

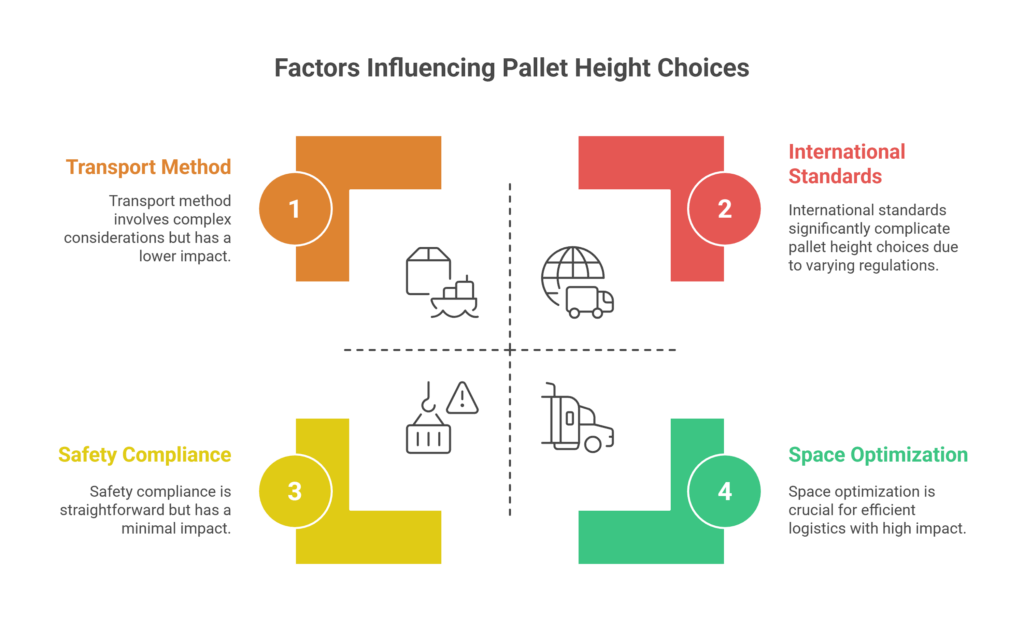

1.Transport Method – Maximum pallet height for sea freight may differ from air or truck shipments due to container door clearance (Freightquote, n.d.).

For example, sea freight containers allow taller pallets compared to air freight, which has stricter height limits because of aircraft cargo door sizes.

2.Safety Compliance – Avoids excessive stacking that could compromise load stability.

In warehouses, pallets stacked too high can topple, causing damage and safety hazards, so companies often limit pallet height to ensure secure loads (NWPCA, n.d.).

3.Space Optimization – Balancing pallet size in feet and height ensures better use of truck or container space.

Logistics firms like FedEx optimize pallet dimensions to maximize cubic utilization of trailers, reducing the number of trips needed (FedEx, n.d.).

4. International Standards – Different countries may have specific regulations for standard shipping pallet dimensions(European Pallet Association [EPAL], n.d.).

For instance, European shipments often require EUR pallet dimensions, which differ from North American standards, affecting height and footprint.

“Balancing transport methods, safety compliance, space optimization, and international standards is key to efficient pallet shipping, as optimizing pallet height can lower costs and increase capacity while ensuring damage prevention and regulatory compliance.”

How can logistics managers best balance maximizing pallet height for cost efficiency while ensuring safety compliance and adhering to varying international pallet standards?

Standard Pallet Height Across Industries

The standard pallet height for shipping can vary widely depending on the industry, product type, and regional shipping regulations. While the typical range is around 48 inches, many industries adopt specific pallet height standards to optimize shipping efficiency and protect goods.

Common Industry Standards

- Retail & Consumer Goods – Often use pallets with a max pallet height of 48 inches to allow easy stacking in distribution centers and fit within store shelving requirements.

- Food & Beverage – Frequently adopt a pallet height limit between 40–48 inches to ensure stability for perishable goods, maintain proper airflow in refrigerated transport, and meet food safety guidelines.

- Automotive – May require lower pallet heights (around 36 inches) for heavy mechanical components to maintain safety and ease of loading.

- Pharmaceuticals – Typically follow strict packaging rules with a standard height of pallet set for compatibility with cleanroom standards, often not exceeding 42 inches.

- E-commerce Fulfillment – Can have varying shipping pallet dimensions based on product types, but often prefer a consistent max pallet height for LTL to optimize warehouse automation.

While pallet sizes vary worldwide, there are common benchmarks that most logistics professionals follow:

- North America (GMA Standard): 48″ x 40″, with a standard height of pallet around 48 inches when loaded.

- Europe (EUR Pallet): 1200mm x 800mm, with a typical loaded height of about 1000mm.

- Asia-Pacific: Multiple standards depending on industry and country.

For LTL freight, delivery pallet size compliance is especially important, since multiple shippers’ freight shares the same truck space (Freightquote, n.d.).

Key Pallet Size Reference Table

| Region/Standard | Base Size (inches) | Base Size (feet) | Typical Loaded Height |

North America | 48 x 40 | 4 x 3.33 | 48″ (standard height of pallet) |

| Europe (EUR) | 47.24 × 31.5 | ~3.94 × 2.63 | 39.37″ |

| Asia-Pacific | Varies | Varies | Varies |

“Different industries set standard pallet heights, usually around 48 inches, to balance efficient stacking, product safety, and regulatory compliance, improving transport and warehouse handling.”

How do different industries balance the need for maximizing pallet height with product safety and regulatory compliance when setting their standard pallet height requirements?

Maximum Pallet Heights by Shipping Method

1. LTL (Less-than-Truckload) Freight

Carriers set their own max pallet height for LTL, commonly around 48 to 60 inches loaded. Staying within this pallet height limit helps avoid reclassification fees (FedEx, n.d.).

Tips for LTL Pallet Loading:

- Stack goods evenly to stay within the maximum pallet height for shipping.

- Avoid overhang to protect your shipping pallet size integrity.

- Use stretch wrap for stability.

2. FTL (Full Truckload) Freight

When you control the entire trailer, you may push beyond the typical max pallet height, but only if it doesn’t compromise safety or violate DOT clearance rules.

3. Sea Freight

For ocean transport, the maximum pallet height for sea freight is often dictated by container dimensions. Standard containers are 8’6” high, while high-cube containers add an extra foot, allowing taller pallet dimensions for shipping.

Sea Freight Pallet Tips:

- Measure pallet size in feet before booking.

- Remember, humidity and stacking pressure can impact product safety.

4. Air Freight

Airlines are strict about standard pallet height for shipping because of aircraft door and hold sizes. Here, the standard shipping pallet dimensions are critical to avoid rebooking fees.

“Managing maximum pallet heights by shipping method helps avoid delays, reduce fees, and protect cargo across LTL, FTL, sea, and air freight shipments.”

Curious how to optimize your shipments across different transport modes? Explore our comprehensive shipping services to streamline your freight and maximize efficiency.

How to Measure and Stay Compliant

1. Measure pallet base (length × width) for normal pallet dimensions

Start by accurately measuring the base of your pallet. This includes the length and width of the pallet platform itself, typically in inches or centimeters. Knowing these normal pallet dimensions ensures your shipment will fit within carrier guidelines and warehouse storage specifications (NWPCA, n.d.).

For example, the standard North American pallet base is 48″ × 40″, but other sizes exist depending on the region and industry. Accurate base measurements help determine if your pallet will be accepted and how it fits in a truck or container.

2. Add the product stack height

After measuring the base, measure the height of the stacked products on the pallet. This means from the top surface of the pallet up to the highest point of the load. Keep in mind irregular shapes or packaging may affect the overall height. This step is critical because the product stack height combined with the pallet base height will determine the total shipment height, impacting load safety and compliance (FedEx, n.d.).

3. Include the pallet base in your normal pallet height total

The height of the pallet itself (usually between 4 to 6 inches) must be added to the product stack height to calculate the normal pallet height. Many forget this step, leading to underestimated total height. Knowing the exact total height helps you stay within the pallet height limit set by carriers or shipping methods, avoiding costly delays or rework (Freightquote, n.d.).

4. Compare to the carrier’s pallet height limit

Once you have the total height (product + pallet base), compare it against the specific carrier or shipping provider’s pallet height limit. Different carriers or freight modes have varying height restrictions. For example, LTL shipments often have stricter height limits (around 48 inches), while FTL or sea freight may allow taller loads. Ensuring your pallet height fits within these limits helps prevent shipment rejection or extra fees.

“Accurate measurement of both pallet base and load height, plus understanding carrier-specific height limits, is essential for compliant and cost-effective shipping, helping to prevent delays, damage, and extra charges.”

What strategies have you found most effective for ensuring pallet height compliance across different carriers and shipping methods?

Best Practices for Palletizing Freight

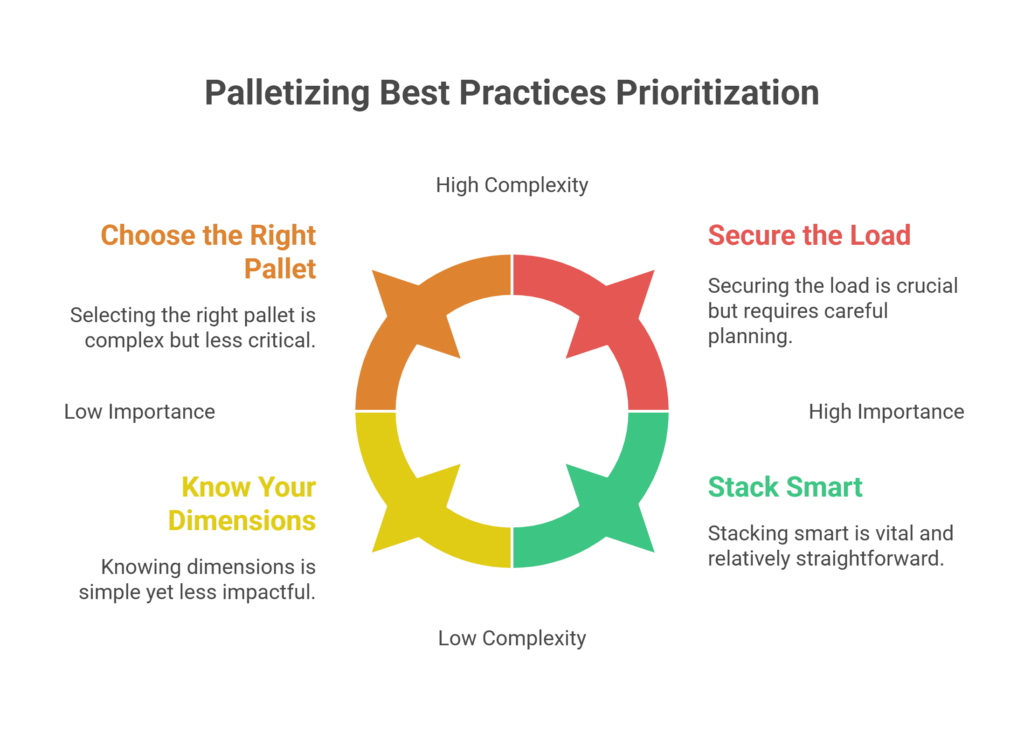

1. Know Your Dimensions

- Pallet dimensions for shipping affect how your freight fits in trailers or containers.

- Measure from the floor to the top of the load for accurate height.

2. Choose the Right Pallet

- Match pallet sizes for shipping to carrier requirements.

- Use high-quality pallets to support heavy or fragile goods.

3. Stack Smart

- Place heavier items at the bottom.

- Avoid overhang to protect goods and comply with delivery pallet size limits.

4. Secure the Load

- Use stretch wrap, strapping, or banding to keep freight stable.

5. Plan for Accessibility

- Ensure forklifts or pallet jacks can easily handle the load.

“Following best palletizing practices, like correct measurements, proper stacking, and secure wrapping, improves load stability, reduces damage, and streamlines handling across the supply chain.”

Want to ensure your pallets are always optimized for safe, efficient shipping? Discover expert tips and tools to perfect your palletizing process with our freight broker solutions.

Frequently Asked Questions (FAQs)

1. What is the maximum pallet height for shipping in LTL freight?

Most LTL carriers set the max pallet height for LTL shipments around 48 to 60 inches, including the pallet base. Staying within this pallet height limit helps avoid extra fees and ensures your freight is accepted without delays.

2. How do I measure the standard pallet height for shipping?

To measure the standard pallet height for shipping, measure the height of the stacked products on the pallet plus the pallet base itself. Typically, this combined height is about 48 inches for many industries, but it can vary depending on your carrier and shipment type.

3. What are the typical shipping pallet dimensions and sizes?

The most common shipping pallet size in North America is 48” x 40”. However, shipping pallet dimensions can vary by region and industry, with European pallets typically sized at 47.24” x 31.5”.

4. What is the maximum pallet height for sea freight?

The maximum pallet height for sea freight usually ranges from 60 to 84 inches, depending on container type and cargo regulations. Always check with your carrier to ensure your pallet height complies with their limits.

5. How big is a shipping pallet and what is the normal pallet height?

A typical shipping pallet size is 48” x 40” with a normal pallet height of about 48 inches when loaded. This size works well for most transport methods, including LTL and full truckload shipments.

Maximize Your Shipping Efficiency

Understanding maximum pallet height standards isn’t just about compliance, it’s key to protecting your profits. Whether managing max pallet height for LTL or sea freight, staying within limits helps avoid damage, fines, and wasted space.

So, how do you ensure your pallet dimensions meet each shipping mode’s requirements? Accurate measurements and strict adherence keep your freight moving smoothly and costs down.

Ready to optimize your pallet shipping? Contact us to get expert advice on maximum pallet height standards and keep your logistics running efficiently.

References

- European Pallet Association (EPAL). (n.d.). EUR Pallet Standards. Retrieved from https://www.epal-pallets.org

- FedEx. (n.d.). Freight Shipping Guidelines. Retrieved from https://www.fedex.com

- Freightquote. (n.d.). LTL Freight Shipping Tips. Retrieved from https://www.freightquote.com

- National Wooden Pallet & Container Association (NWPCA). (n.d.). Pallet Standards and Guidelines. Retrieved from https://www.palletcentral.com