Modern supply chains operate across continents, rely on countless suppliers, and depend on unpredictable global markets. With so many moving parts, risks are not the exception, they’re the expectation. Whether you’re a logistics coordinator, operations leader, or business owner, understanding the types of risk in supply chain management can help you protect your operations and build long-term resilience. In this blog, we’ll explore, the main types of supply chain risks, How to categorize and manage disruptions and, Real-world supply chain risks examples. Let’s break it down.

What Are the Main Types of Risk in Supply Chain Management?

Supply chains face a wide range of risks, from physical disasters to digital threats. Here are the major types of risk in supply chain management that every business should know:

a. Operational Risks

- Equipment breakdowns: Unexpected failures in machinery or logistics tools can halt production lines, cause delivery delays, and increase repair costs (Deloitte, 2023).

- Process inefficiencies: Inefficient workflows or outdated processes reduce output, create bottlenecks, and can lead to increased waste and labor costs.

- Labor shortages: A lack of skilled workers, strikes, or high turnover rates can disrupt production schedules and impair service levels (Bureau of Labor Statistics, 2024).

b. Financial Risks

- Price volatility in raw materials: Fluctuations in the cost of commodities like oil, metals, or agricultural inputs can dramatically impact margins and forecasting (World Bank, 2024).

- Currency fluctuations: Shifting exchange rates can increase costs or reduce revenues for companies operating across multiple currencies.

- Credit risk from suppliers or buyers: When suppliers or customers fail to meet payment obligations, it can result in cash flow shortages and supply interruptions.

c. Strategic Risks

- Misaligned partnerships: Poor alignment between a business and its suppliers or distributors can lead to conflicts in goals, delays, or quality issues.

- M&A disruptions: Mergers or acquisitions can lead to uncertainty, integration issues, and temporary service disruptions.

- Poor forecasting: Inaccurate demand forecasting can result in overproduction or stockouts, both of which are costly and damaging to reputation (Gartner, 2024).

d. Compliance and Regulatory Risks

- Trade restrictions: Tariffs, embargoes, or new export rules can limit access to key markets or make goods more expensive (WTO, 2023).

- Environmental regulations: Changing sustainability laws and emissions standards require operational adjustments and can increase compliance costs.

- Changing import/export rules: New customs procedures or documentation requirements can delay shipments and complicate cross-border transactions.

These supply chain risk categories allow companies to assess threats based on where and how they originate, giving them a roadmap for mitigation.

“Understanding the core types of supply chain risks is the foundation for creating a resilient strategy.”

What type of supply chain risk do you think is most overlooked in your industry?

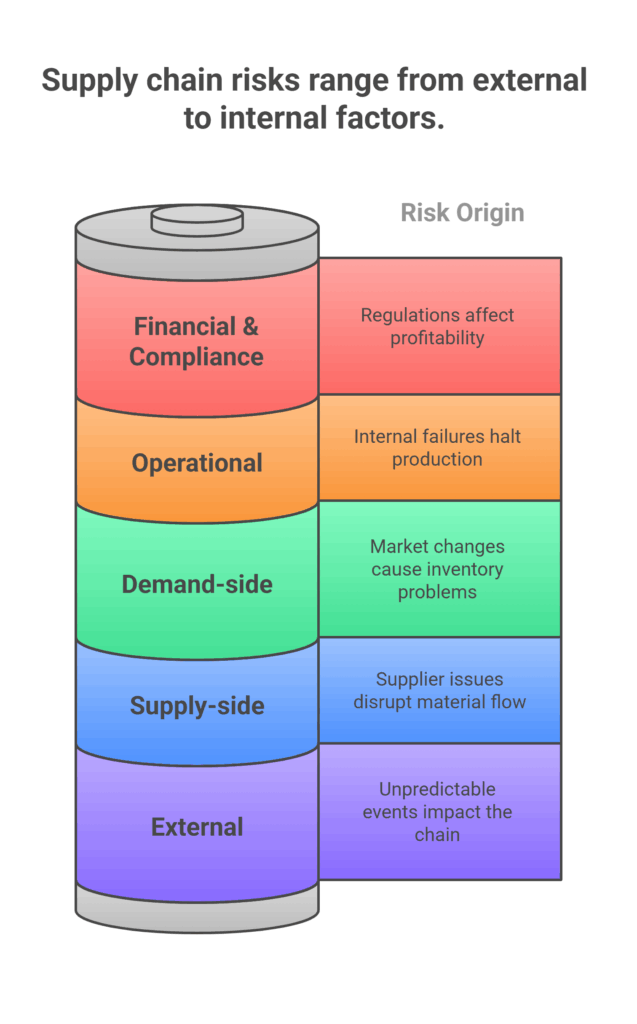

Supply Chain Risk Categories You Need to Track

To manage risk, you need a structure. Experts often break risks down into five core supply chain risk categories:

- External (Environmental) – Weather events, pandemics, geopolitical unrest

- Supply-side Risks – Supplier bankruptcy, delivery delays

- Demand-side Risks – Forecast inaccuracies, sudden spikes in demand

- Operational Risks – Equipment or process failures

- Financial & Compliance Risks – Tariffs, audits, price instability

Understanding these types of supply chain risks helps in assigning mitigation strategies to each category, instead of reacting blindly to every crisis.

“Breaking down risks into categories helps supply chain teams prioritize action, assign responsibility, and reduce blind spots.”

How does your organization currently categorize and monitor supply chain risks, and where could your system improve?

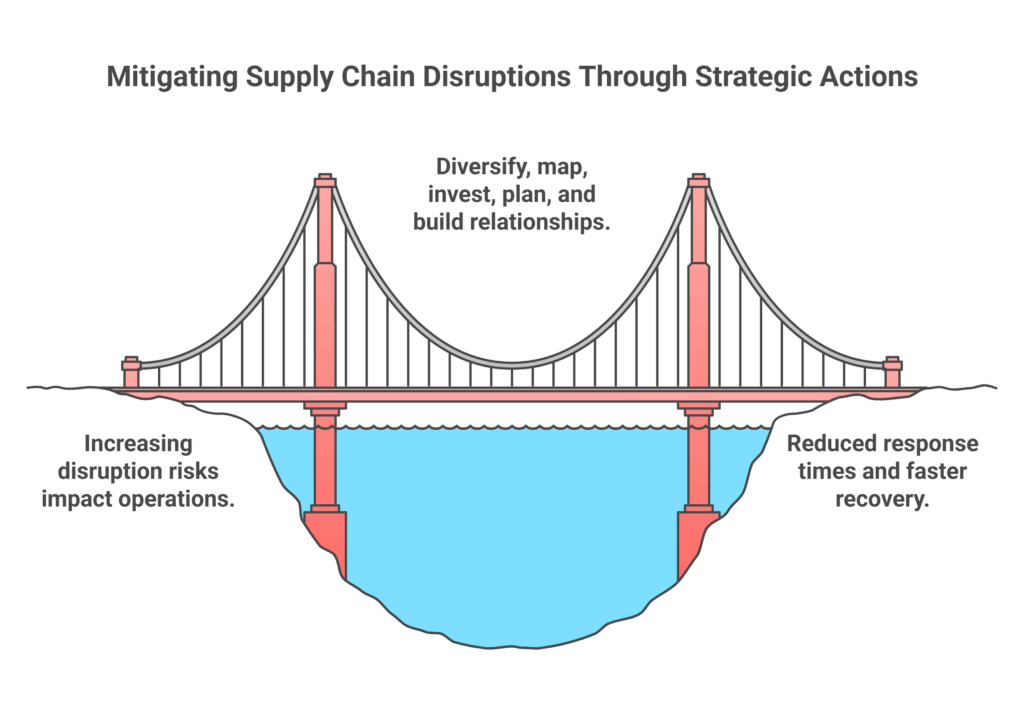

How to Handle Supply Chain Disruption Risks

Every supply chain leader must face the hard truth: Supply chain disruption risks are increasing and faster than ever before.

Here’s how to stay ahead:

-

Map your supply chain end-to-end

- Know where your materials come from and how they move.

-

Diversify suppliers

- Don’t rely on a single region or vendor. 90% of companies are now actively seeking nearshoring or multiple sourcing options (Deloitte, 2023).

-

Invest in supply chain visibility tools

- Use real-time dashboards and predictive analytics. Companies using AI-based monitoring reduce disruption response time by 30% (Gartner, 2024).

-

Create contingency plans

- Predefine alternate suppliers, shipping routes, and budgets.

-

Build strong relationships

- Strong communication with vendors and partners pays off in crisis. Businesses with collaborative supplier relationships recover 20% faster from major disruptions.

The reality is, supply chain disruption risks are not going away. But preparation reduces the impact.

“Risk mitigation isn’t about preventing every disruption, it’s about responding faster and smarter.“

Looking for expert help with freight compliance and disruption management? Explore our solutions.

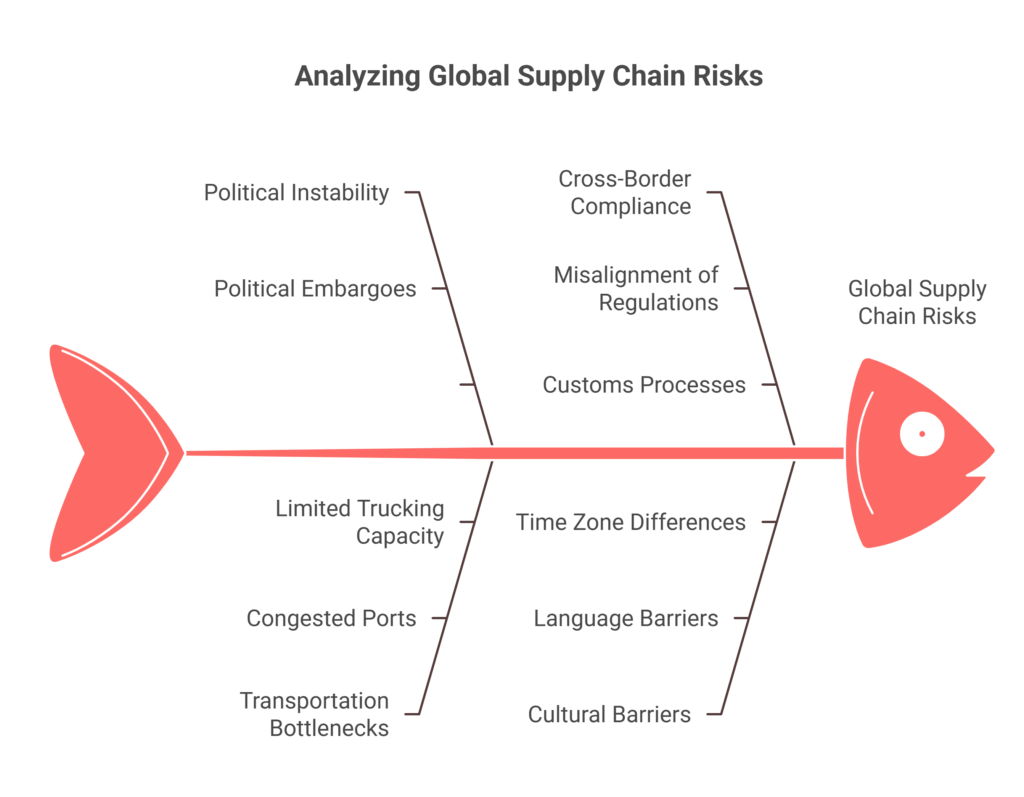

Navigating Global Supply Chain Risks

Globalization brings opportunity and new threats. From political instability to cross-border regulations, global supply chain risks must be managed strategically.

Common global risks include:

- Political embargoes or wars: These events can halt trade entirely in affected regions, limit access to critical resources, or lead to sudden regulatory changes that impact contracts and delivery routes (WTO, 2023).

- Transportation bottlenecks: Congested ports, limited trucking capacity, or overburdened rail systems can delay deliveries, drive up costs, and reduce responsiveness to customer demand (FreightWaves, 2023).

- Cross-border compliance issues: Misalignment between country-specific regulations, customs processes, and required documentation can lead to fines, shipment holds, or legal liabilities.

- Cultural or communication barriers: Misunderstandings due to language, time zones, or business practices can delay decision-making, strain partnerships, and introduce costly errors in execution.

These global supply chain risks can quickly spiral if you lack visibility, diversified sourcing, or flexible planning.

“Global risk navigation demands local insights, agile planning, and strategic partnerships.”

Which global supply chain risk has had the biggest impact on your business in the past two years?

Real-World Supply Chain Risks Examples

Let’s make it practical. Here are some supply chain risks examples from recent years:

- Semiconductor shortage: Affected global electronics, automotive, and manufacturing sectors.

- Port congestion during COVID-19: Slowed down deliveries, caused product stockouts.

- Suez Canal blockage: Delayed billions in cargo for weeks.

- Cyberattacks on logistics platforms: Paralyzed distribution and communication for major players.

These are just a few top supply chain risks that caught even the most prepared companies off guard.

“Real-world disruptions reveal how even the strongest supply chains can break without warning.”

Looking for supply chain risk solutions tailored to your operation? Explore our freight broker solutions.

Frequently Asked Questions

1. What are the different types of risk in supply chain management?

There are several types of risk in supply chain management, including operational, financial, strategic, and compliance-related risks. Each poses a unique threat to business continuity and must be managed through proactive risk mitigation strategies.

2. What are some examples of supply chain risks companies face today?

Some common supply chain risks examples include supplier bankruptcy, transportation delays, political unrest, and cyberattacks. Companies must be prepared for both frequent and rare disruptions by diversifying suppliers and using predictive analytics.

3. How are supply chain risk categories used in real business scenarios?

Supply chain risk categories, such as external, operational, and financial risks help organizations prioritize, allocate resources, and develop targeted responses. They are an essential tool in assessing global supply chain risks and building resilient operations.

Don’t Just React, Strategize

Yes, the supply chain industry challenges are daunting. And yes, supply chain concerns range from inflation to extreme weather to supplier insolvency. But companies that actively manage the types of risk in supply chain management will be better positioned to grow, even in uncertainty.

Understanding the landscape of types of supply chain risks and tracking supply chain risk categories is not just smart; it’s essential. Whether you’re facing small delays or massive shocks, preparedness is your competitive edge.

Ready to mitigate risk and strengthen your supply chain? Contact us to gain expert guidance and streamline your risk strategy with confidence.

References

- Bureau of Labor Statistics. (2024). Labor market trends. Retrieved from https://www.bls.gov

- Deloitte. (2023). Global supply chain survey. Retrieved from https://www2.deloitte.com

- FreightWaves. (2023). Port congestion and trends. Retrieved from https://www.freightwaves.com

- Gartner. (2024). Supply chain analytics. Retrieved from https://www.gartner.com

- World Bank. (2024). Commodity price forecasts. Retrieved from https://www.worldbank.org

- WTO. (2023). Global trade policy updates. Retrieved from https://www.wto.org