One of the main roles in the logistics industry involves the movement of goods. In the ecommerce industry, this can be anything from clothes to food. However, there are times when heavy machinery and tools need to be moved, and in cases like these, there are special requirements needed. Due to this, efficiency is often low for equipment shipping in the supply chain, and there is much room for improvement.

If you want to get ahead of the competition in the equipment shipping industry, then we have all the information you need. We’ll be covering everything from how equipment shipping services affect the supply chain, how you can improve these services, and future trends to look out for.

Let’s get started!

The role of equipment shipping services in supply chain management

Equipment shipping services are very crucial for moving different types of items from heavy machinery and industrial parts to tools and specialized equipment as well. These services focus on the manufacturing, construction, and energy sectors, which require the timely delivery of equipment and its safety. Depending on its size, weight, and where it is going equipment can be shipped using a number of different methods as well. Road transport for regional deliveries, rail for bulk shipments, air freight when urgent needs are required, and sea freight are almost always employed for international or oversized cargo.

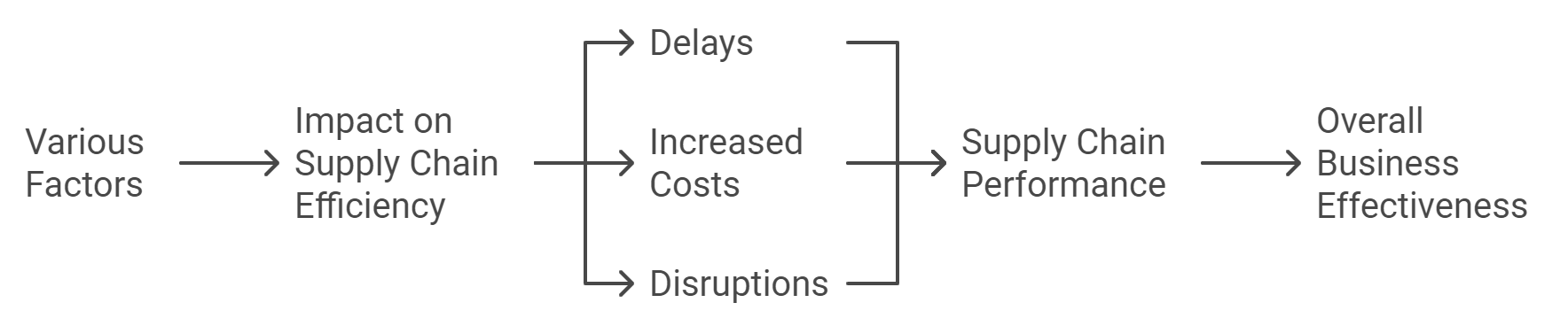

Equipment shipping is an essential point of interest in a bigger strategic plan — because it should seamlessly work with all other supply chain functions like warehousing, inventory management, or distribution. It ensures that the equipment comes when and where required so every production or operational process goes smoothly. Good collaboration between shipping and other logistics processes keeps stocks at a minimum, minimizes waiting time, and sustains just-in-time delivery structures. Efficient delivery of equipment improves the flow of items in a supply chain, ultimately increasing business efficiency and competitiveness.

Impacts on Supply Chain Efficiency

Positive impacts

Improved delivery times

In a world where time is truly money, quick delivery times are essential to efficient supply chains, making equipment shipping services an absolute necessity. This, in turn, allows production processes to continue unimpeded and helps prevent costly downtime. Consistent and on-time deliveries also enhance customer satisfaction by meeting or exceeding expectations.

Providing quicker turnaround times also allows the company to respond more quickly to market needs, further reducing lead time and improving overall logistics flexibility. This is especially essential in industries where equipment determines the success of operations, ensuring that projects continue to run on time and meet deadlines.

Enhanced inventory management

In the supply chain, timely equipment shipping means maintaining optimal inventory levels. By ensuring deliveries arrive on the expected date, companies can manage their inventories more efficiently by eliminating over- or understocking. This balance reduces holding costs and the risk of obsolescence.

Efficient shipping also enables just-in-time inventory strategies, as equipment can be delivered exactly when it is needed for production. This synchronization of shipping with inventory management allows for seamless operation and reduced storage charges, as well as ensuring that the supply chain is more responsive, thus enhancing overall business performance.

Cost reduction

Efficient equipment shipping services contribute significantly to cost reduction in the supply chain. Companies can reduce their transportation and handling costs by optimizing shipping routes, consolidating shipments, and selecting the best-value means of transport. Good shipping solutions also help with fewer chances of delays, which can result in expensive fines or extra charges to fix the issue.

In addition, the prevention of overstock through just-in-time deliveries eliminates warehousing costs. In short, efficient equipment shipping leads to improved operational efficiency in the business, which allows for more strategic use of resources and preserved price competitiveness.

Negative impacts

Delays and disruptions

When your equipment transportation is not from a reliable source, then you can face huge setbacks and disruptions in the flow of the supply chain. Late or unexpectedly delayed shipments put production processes to a halt, causing missed deadlines and longer project timelines. The ripple effect of these delays can then be traced back through the supply chain to previous stages in production and distribution.

Moreover, frequent interruptions can negatively affect a business’s brand image, disappointing customers or possibly causing more sales losses. Poorly managed shipping service providers contribute to additional uncertainty and make it difficult for companies to efficiently plan their operations, consequently leading to inefficiencies that could be easily avoided.

Increased costs

Inefficient shipping often costs more in the supply chain. This can lead to delays, misrouted shipments, and an increased need for expedited deliveries, which all result in rising costs. Furthermore, companies may be required to keep more inventory on hand as a cushion for delays caused by these services, adding warehousing and storage costs.

Lost or damaged equipment in transit is another potential add-on cost, including repairs, replacements, and insurance claims. It is important to know that all sources of waste lead directly or indirectly to cost. These costs affect budgets and market pricing, hurting margins, which reflects on the company’s financial performance.

Quality issues

Logistics efficiency is also being impeded due to the damage during transit, which has led to quality issues. Poor handling, insufficient packaging behavior, or unsuitable shipping practices can cause any equipment arriving to be damaged and not working properly. This disrupts production as well as requires more time and resources to replace or repair the damaged components.

Moreover, consistent occurrences of bad quality can destroy the confidence consumers and allies place in your company, which may stain its reputation for life. Re-shipping equipment also leads to longer lead times in certain instances, creating additional inefficiencies and increasing the total costs of ownership.

Strategies for improving equipment shipping services

So, you’ve seen both the positive and negative impacts equipment shipping has on the supply chain. If you’re noticing your company is experiencing more negative impacts, then you might need to make some changes. Here are the strategies you should use:

Optimizing shipping processes

Optimizing the shipping process is necessary to improve efficiency and make all equipment shipments more reliable. This approach encompasses everything from pricing the proper transportation methods to orchestrating delivery logistics. And a most important part to consider is how well your shipping partners can meet all of these requirements and equipped with a team you know can handle the equipment effectively.

Companies must also use this technology to automate and organize other processes like route planning, tracking inventories, etc. To address this, businesses are implementing advanced tracking systems and logistics software to track their shipments in real-time to proactively handle issues and ensure on-time deliveries. Moreover, optimizing packaging and handling procedures can avoid delivering faulty or damaged goods during transit.

Another way to ensure the shipping strategy complies with a company’s changing needs and market conditions is by conducting regular reviews and audits of its current fulfillment strategies, which can help identify improvement areas.

Enhancing communication

Communicating effectively is one of the most critical methods for achieving better equipment shipping services. Maintaining accessible, open channels among all involved parties creates a straight-flowing supply chain. It goes back to creating effective alignment between shippers, suppliers, and customers so that all parties understand any shipment’s specifics, timelines, and expectations.

Good communication will prevent misunderstandings, cause errors to be reset quickly, and make problem-solving run smoothly. It also gives minute-by-minute information on the timing of deliveries via tracking systems and communication platforms. Such updates empower both sides to see how things are stubbing out, predict any potential delays ahead of time, and adapt schedules or plans as needed.

Clarity of communication is also directly related to the strength of relationships with logistics partners, enabling secured and more flexible service regarding extra requests or any changes. When businesses favor open and transparent communication every step of the way in shipping, it will help both parties be on the same page, leading to increased coordination and better customer satisfaction, which indirectly boosts the chain’s efficiency.

Implementing best practices

Employing best practices is a tactical way of ensuring the standard and reliability of equipment shipping services. Pursuing best practices and industry standards for shipping will lead to safe, efficient, and cost-effective means of transport.

A best practice is to optimize packaging and handling processes to prevent damage to equipment during transportation. This should be in accordance with packing norms, which can include using specific materials, securing methods, and following industry-specific principles for packaging. Performing regular reviews and audits of shipping processes is another best practice to uncover areas that could be optimized and ensure compliance with industry standards. They aim to find inefficiencies, reduce risk, and maintain high-quality services.

Finally, keeping up to date with the most recent technologies in shipping and logistics is also a great way that your system can evolve into something more efficient. Their use will help businesses avoid shipping errors, cut costs and improve the overall trustworthiness of their supply chain.

Adopting innovative solutions

Implementing innovative technologies has become a forward-thinking approach, and it can seriously boost the efficiency and effectiveness of your typical provider. It encompasses adopting current practices and innovative systems to address contemporary logistical challenges. The key advancement is the application of automation and robotics within warehousing and shipping operations to decrease time-to-fulfillment, human error, and delivery times. Sorting, packing, and loading are done more efficiently with automated systems.

Another innovation that serves well is transforming to more environmentally friendly shipping practices like greener packaging materials, optimizing routes for less fuel consumption, or utilizing electric and hybrid vehicles. Such initiatives reduce environmental impact and also, over the longer term, enhance cost efficiency.

You can also leverage digital platforms and analytics to gain more visibility into shipping performance, providing data-backed decision-making mechanisms for continuous improvement. Implementing these modern solutions allows businesses to remain competitive, thus providing customers with exactly what they need and guaranteeing a more efficient supply chain.

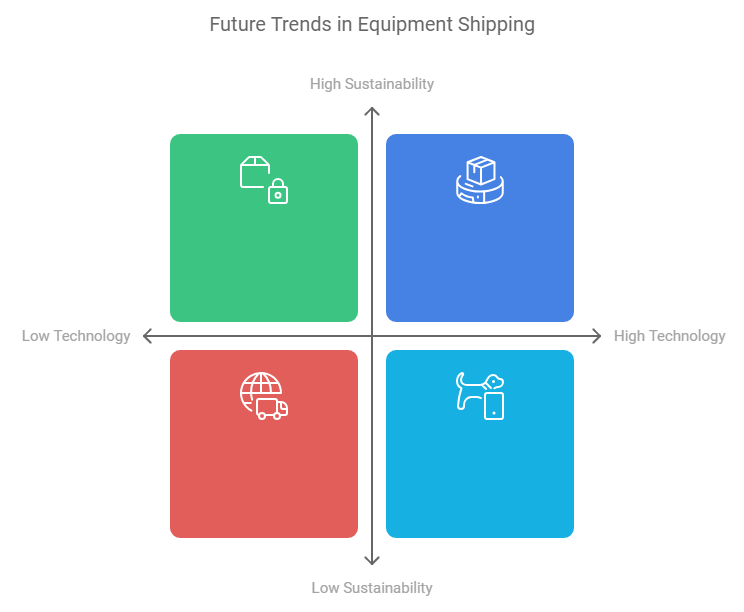

Future trends in equipment shipping and supply chain efficiency

If you want to stay ahead of the competition, consider some of these future trends in the industry.

Advancements in technology

Technological advancements are changing the face of equipment shipping and optimizing supply chain performance. New technologies make real-time tracking of products possible, and predictive analytics, enabled by blockchain, allow decision-makers to have greater forecasting ability and secure transparent transactions.

Companies can use IoT devices to track the conditions of their equipment and where it is in transit at all times, which minimizes any possible damages due to no delays. Route planning and inventory management are optimized with the help of AI, which expedites faster-in-transit times and reduces costs. By keeping records of every transaction, blockchain brings transparency and trust to the supply chain. These technological advancements are improving efficiencies, reliability, and the speed of shipping items.

Evolving customer expectations

Changing customer expectations is the new frontier for shipping equipment as customers require quicker, more dependable, and flexible routes. This is further compounded by the rise of e-commerce and consumer expectations for fast delivery, forcing companies to ensure their shipping rate processes are as efficient as possible. This has led to customers expecting real-time tracking, clear communication, and environmentally friendly implementations.

In addition, they want tailored services, such as home deliveries at the time of their choice or individually wrapped products. To address these requisites, businesses are pivoting to newer technologies, strengthening logistics networks, and embracing a customer-centric approach. As customer expectations evolve, businesses must change with them or risk losing their competitive edge and alienating customers.

Conclusion

Equipment shipping is a lucrative sector in the logistics industry, but it needs to be done right. If not, it can have many negative impacts on the supply chain. By following the strategies we have provided you, you will only see the positive impacts and be able to stay on top of your competition, increase your revenue, and grow as a company.

For additional help, you should work with a 3PL provider such as SPI Logistics. We have a wide range of experts who can handle the entire supply chain for you, ensuring equipment gets from A to Z as seamlessly as possible and increasing customer satisfaction. Contact us today to find out how you can get started.